Everyone has heard of gears and can picture them meshing together. Maybe a picture of an old factory comes to mind where they undergo never-ending turns doing whatever it is they do. At its core, all a gear does is transmit power with uniform rotary motion, but they help us do much more. You might not realize this because gears usually work tirelessly under the hood (sometimes literally). This makes us take them for granted since we rarely actually see them. Allow me to make them more visible for you with the following examples, some of which you may not have realized had gears! You’ll also see how Wenzel plays an important role in the life of these gears.

You may be carrying some gears with you at this moment. Your wristwatch may have dozens of them that work in conjunction to keep time exactly and current. These tiny gears are still cut with shapers and mills but at a much smaller scale. Even though it is often a quartz crystal that provides the constant frequency of time, it is the synchronicity of all of these small gears which help move the second, minute, and hour hands as well as calendars and other hands.

You may be carrying some gears with you at this moment. Your wristwatch may have dozens of them that work in conjunction to keep time exactly and current. These tiny gears are still cut with shapers and mills but at a much smaller scale. Even though it is often a quartz crystal that provides the constant frequency of time, it is the synchronicity of all of these small gears which help move the second, minute, and hour hands as well as calendars and other hands.

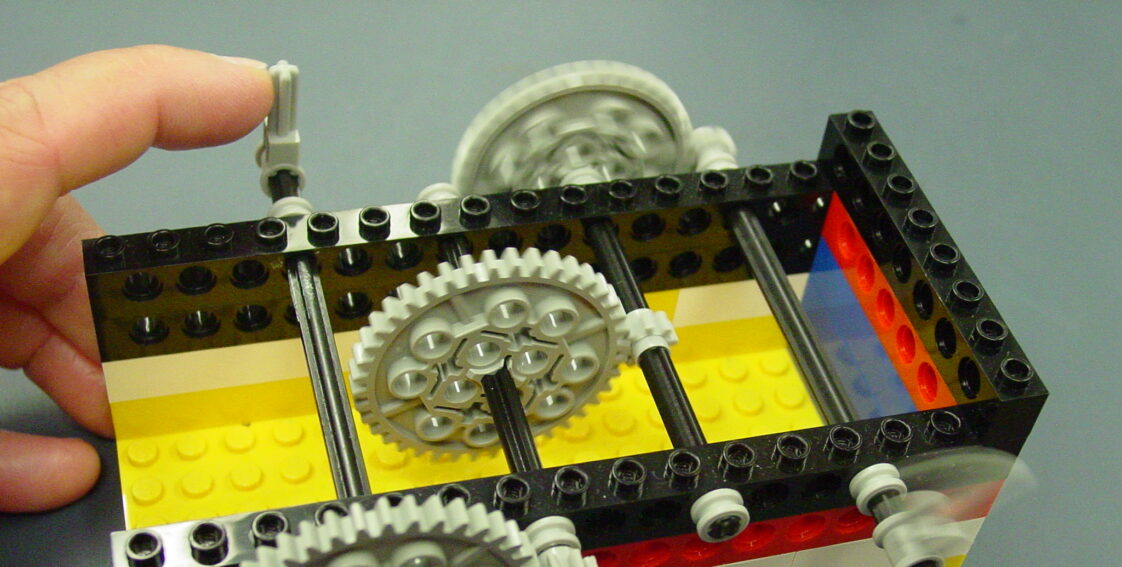

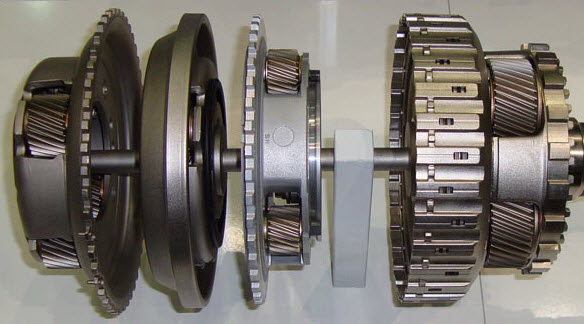

Of course, cars need gears to transmit the rotary motion from the engine to the axles and, finally, to the wheels. In the engine, planetary gear sets like the ones shown in the picture are used to keep the engine running at peak efficiency just like you would have to on a bicycle. Even though they are made up of multiple gears, many transmission ratios can be achieved while keeping the working volume small. Usually used in automatic transmissions, some of today’s cars can have as many as 13-speed transmissions! Made up of spur and helical gears, these are the bread and butter for Wenzel gear inspection machines.

Of course, cars need gears to transmit the rotary motion from the engine to the axles and, finally, to the wheels. In the engine, planetary gear sets like the ones shown in the picture are used to keep the engine running at peak efficiency just like you would have to on a bicycle. Even though they are made up of multiple gears, many transmission ratios can be achieved while keeping the working volume small. Usually used in automatic transmissions, some of today’s cars can have as many as 13-speed transmissions! Made up of spur and helical gears, these are the bread and butter for Wenzel gear inspection machines.

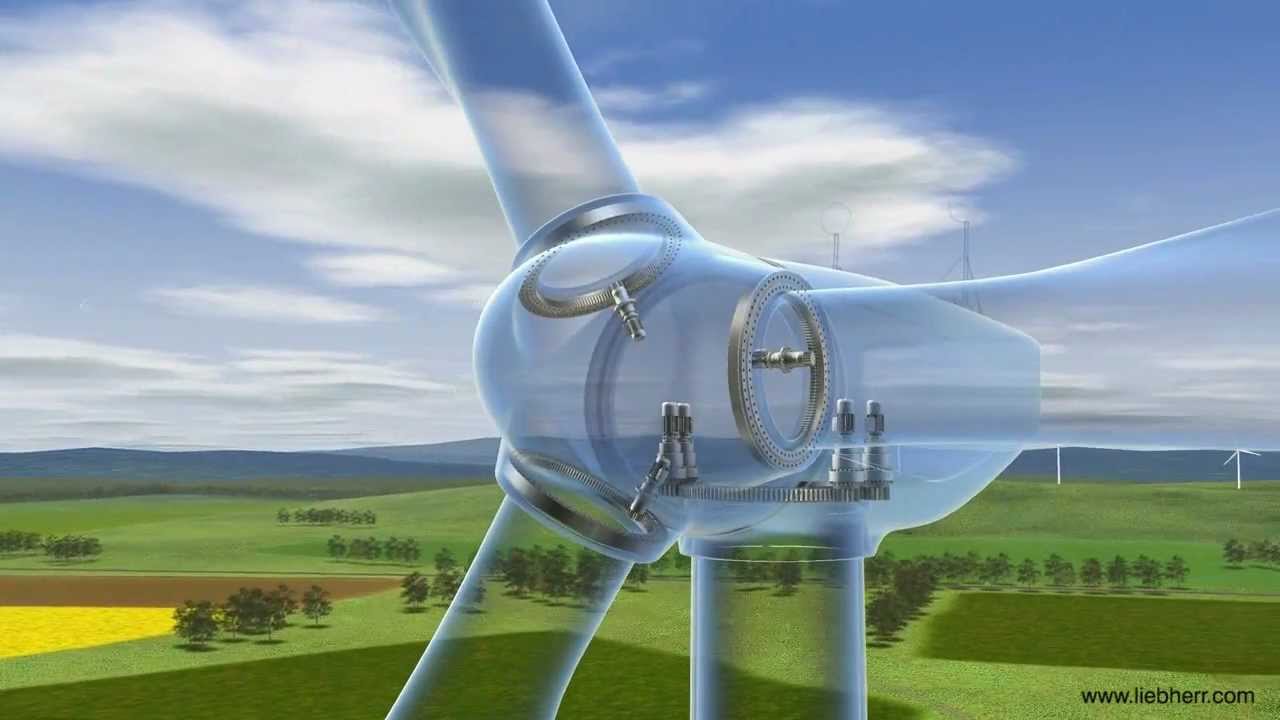

While driving said car, a helpful energy resource you may have seen in the  distance are wind turbines. These behemoths harness wind power and turn it into electricity. Not only do they use gears to turn the mill in the direction of the wind for maximum harnessing, but the blades can sometimes turn as well. This is achieved by using gears as big as 6 meters! How are these gears inspected? You guessed it – a large Wenzel gear inspection machine!

distance are wind turbines. These behemoths harness wind power and turn it into electricity. Not only do they use gears to turn the mill in the direction of the wind for maximum harnessing, but the blades can sometimes turn as well. This is achieved by using gears as big as 6 meters! How are these gears inspected? You guessed it – a large Wenzel gear inspection machine!

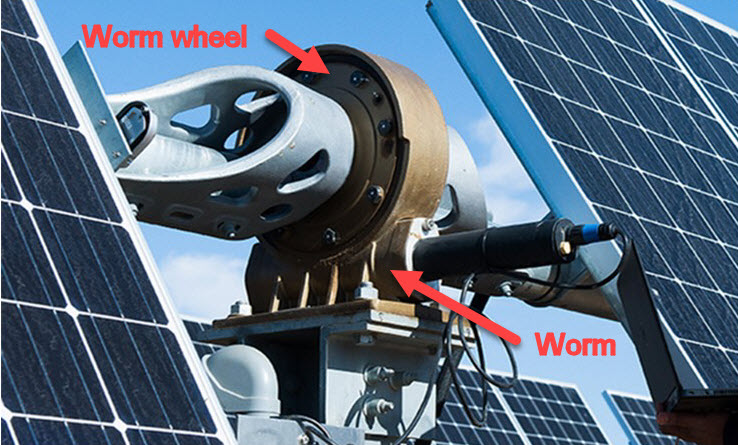

A bigger sector in energy is the solar power industry. Solar panels use photovoltaic cells to store power and convert it to electricity as well. However, since the earth rotates around the sun, so must the solar panels rotate so that they face the sun. Rotating solar panels use a slewing drive that contains a worm wheel and worm gear.

A bigger sector in energy is the solar power industry. Solar panels use photovoltaic cells to store power and convert it to electricity as well. However, since the earth rotates around the sun, so must the solar panels rotate so that they face the sun. Rotating solar panels use a slewing drive that contains a worm wheel and worm gear.

For massive transportation, ships use giant gearboxes like the one in the picture. These center-relieved double-helical designs transmit massive torque in diesel engines. The picture adjacent shows a reduction gearset that drops the high engine RPMs to lower RPMs for the propeller.

For massive transportation, ships use giant gearboxes like the one in the picture. These center-relieved double-helical designs transmit massive torque in diesel engines. The picture adjacent shows a reduction gearset that drops the high engine RPMs to lower RPMs for the propeller.

From the massive to the minute once again, you should be seeing these guys at least twice a year. Your dentist has drills that use some of the smallest gears needed in these high-speed applications. In order to measure these parts, I needed to use a needle stylus instead of a conventional ruby stylus. The needle stylus had a tip with a diameter of 0.1 mm. I’ve used this stylus to measure a gear with a module as small as 0.15!

Here at Wenzel, we can measure all of these types of gears and more to ensure that these tools and structures are efficient at what they do, last longer, make less noise, and make the world a better place. If you want us to help you with this mission, contact me here or visit us here. And don’t forget to follow me on Twitter @GearMarks! #Cheers4gears