What is Viscose Rayon?

Rayon is the oldest commercial man made fiber. It is a manufactured fiber composed of regenerated cellulose, as well as manufactured fibers composed of regenerated cellulose in which substituents have replaced not more than 15% of the hydrogens of the hydroxyl groups. Rayon fibers include yarns and fibers made by the viscose process, the cuprammonium process, and the now obsolete nitrocellulose and saponified acetate processes. Generally, in the manufacture of rayon, cellulose derived from wood pulp, cotton linters, or other vegetable matter is dissolved into a viscose spinning solution. The solution is extruded into an acid-salt coagulating bath and drawn into continuous filaments. Groups of these filaments may be made in the form of yarns or cut into staple. Of all the regenerated cellulosic fibers viscose is by far the most important. There are many manufacturers throughout the world. In this article I will discuss physical, chemical and mechanical properties of viscose rayon.

Viscose rayon is made by converting purified cellulose obtained from wood pulp into xanthate, dissolving the xanthate in dilute caustic soda and then regenerating the cellulose from the product. Wet strength of ordinary viscose rayon is quite low, and this is a great disadvantage. Further, its ability to recover from small deformations is also not good, and this is the reason why viscose rayon fabrics have poor dimensional stability. Being a cellulosic fiber, its chemical properties are similar to those of cotton, particularly with respect to affinity to dyes, etc. However, as considerable breakdown of the natural cellulose molecules takes place during the manufacturing process, viscose is attacked by strong oxidizing agents; acids attack viscose more quickly than they do cotton. While strong solutions of alkali cause swelling with loss in strength. An interesting fact with viscose is that it attains the maximum swelling in 9% concentration caustic soda, while cotton swells at maximum of 18% concentration. This differential behavior necessitates very careful handling during mercerization of cotton-viscose blends.

Viscose has much lower resistance to acids and bleaching agents than cotton and is discoloured and weakened when attacked by mould and fungi.

Characteristics of Rayon Fiber:

- Highly absorbent

- Soft and comfortable

- Easy to dye

- Drapes well

The drawing process applied in spinning may be adjusted to produce rayon fibers of extra strength and reduced elongation. Such fibers are designated as high tenacity rayons, which have about twice the strength and two-thirds of the stretch of regular rayon. An intermediate grade, known as medium tenacity rayon, is also made. Its strength and stretch characteristics fall midway between those of high tenacity and regular rayon.

Physical Properties of Viscose Rayon:

Viscose rayon fiber has a density of 1.52 g/cm3, higher than all other natural fibers and also higher than most synthetic fibers. Thus, fabrics made of pure rayon fiber are usually heavier than those made of other fibers at fixed fabric thickness. Important physical properties of viscose rayon are described below.

1. Moisture Absorption

It absorbs more moisture than cotton. Moisture Content of Cotton is 6% at 70 deg F and 65% RH, and for Viscose Rayon it is 13% under the same conditions.

2. Tensile Strength

The Tensile Strength of the fiber is less when the fiber is wet than when dry. It is 1.5-2.4 gpd in the dry state and 0.7-1.2 gpd in the wet state. For high tenacity variety the values are 3-4.6 gpd and 1.9 to 3.0 gpd.

3. Elasticity

The elasticity of Viscose Rayon is less than 2-3%. This is very important in handling viscose yarns during weaving, stentering etc when sudden tensions are applied.

4. Elongation at Break

Ordinary Viscose rayon has 15-30% elongation at break, whule high tenacity rayon has only 9-17% elongation at break.

5. Density

The density of Viscose rayon is 1.53 g/cc. Rayon filaments are available in three densities: 1.5, 3.0 and 4.5.

6. Action of Heat and Light

At 300 deg F or more, VR loses its strength and begins to decompose at 350-400 deg F. Prolonged exposure to sunlight also weakens the fiber due to moisture and ultraviolet light of the sunlight.

Chemical Properties of Viscose Rayon:

Viscose rayon consists of cellulose of lower DP than cotton cellulose. Also amorphous region of Viscose rayon is present to a greater extent, therefore, Viscose rayon reacts faster than cotton with chemicals. Acids like H2SO4 HCL breaks the cellulose to hydrocellulose. Oxidising agents like Na(OCl)2, Bleaching powder, K2Cr2O7, KMnO4– form oxycellulose. Cold acid solutions for a short time do not attack viscose rayon. Essential chemical properties of viscose rayon are described below.

1. Action of Acids

The resistance of regenerated cellulose rayon’s to acids is generally less than that of cotton to the same concentrations of the same acids. Therefore, acid treatments must not be too drastic with respect to concentration, temperature and time. Organic acids can be safely used in 1 to 2 percent concentration without injury to the fiber. Inorganic acids such as hydrochloric and nitric can be used in surprisingly strong concentrations provided the temperatures are not too high and the treatment is brief. Oxalic acid for removal of iron stains is not recommended except at temperatures lower than 150°F. At high temperatures and concentrations all acid will destroy or carbonize regenerated rayon’s. No harmful action will result if applied at 0.5 to 3 percent solution at room temperature.

2. Action of Soaps

Ordinary soaps in usual textile concentration have no direct effect on regenerated cellulose materials. Improper use of soap or use of poorly made soap results in rancidity and odor in rayon fabrics or yarns. When soaps alone is used ,there is a tendency for the ionized fatty acid from the soap to adhere tenaciously to the individual rayon filaments. During the drying filament of such materials and subsequent storage .The free fatty acid radical is very likely to turn rancid and to give the goods and objectionable odor. This phenomenon is specially Prevalent on oil-delustered rayons, because the fatty acid radical of the soap adheres Tenaciously to the minute oil globules in the structure of the yarn.If given time enough the fatty acid radical

3. Action of Dry Heat

Most regenerated celluloses, under the influence of heat as well as light, show rapid loss in strength, this change being accompanied by a increase in copper number and alkali solubility. In a study of effect of drying conditions of textile yearns, Wiegerink in 1940 showed that the quality index of cellulose fibers decreases either as the temperature is increased or as the moisture content of the surrounding atmosphere is increased. Both the breaking strength and fluidity of viscose rayon appear to be functions of the relative humidity to which the samples are exposed. Degradation of cellulose is lower in the absence of oxygen. Continued heating, however, in the absence of oxygen leads to deterioration of the cellulose but little is known about the course of the reactions. Short heating at high temperatures, such as 140°C is less harmful than long heating at lower temperatures. A decrease of tenacity and eventually a yellow to brown discoloration occurs on aging.

4. Action of Solvents

Textile solvents can be used on Viscose rayon without any deteriorating effect. Viscose rayon dissolves in cuprammonium hydroxide solution.

5. Effect of Iron

Contact with iron in the form of ferrous hydroxide weakens viscose rayon yarns. Therefore staining, marking or touching of rayon to iron or iron surface should be avoided.

6. Action of Microorganisms

Microorganisms (moulds, mildew, fungus, bacteria) affect the color, strength, dyeing properties and luster of rayon. Clean and dry viscose rayon is rarely attacked by moulds and mildew.

Viscose Fiber Mechanical Properties

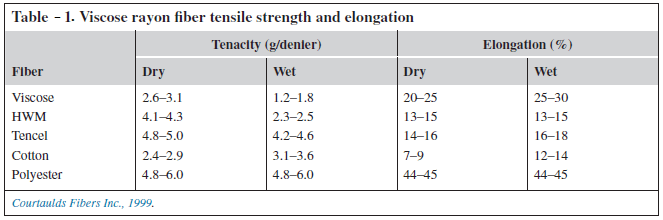

As with other textile fiber materials, tensile strength and breaking elongation are two of the most important mechanical properties for viscose rayon fiber. Fiber tensile strength is often expressed by tenacity with a unit of force per denier or tex. Table-1 lists tensile strengths and elongations of viscose rayon compared to HWM viscose, tencel, cotton, and polyester.

Viscose rayon fiber has a lower tensile strength under wet conditions (e.g., during washing) than under dry conditions. This difference can be greater than a factor of 2. Another mechanical feature of viscose rayon fiber is its substantially high elongation, up to 25% (dry) and 30% (wet). Therefore, viscose rayon or rayon blended fabrics tend to have good stretchability. In comparison, HWM viscose fiber shows a higher tensile strength in both dry and wet conditions, but a lower elongation at break.

References:

- Textile Raw Materials By Ajay Jindal and Rakesh Jindal

- Introduction to Textile fibers by V. Sreenivasa Murthy

- Textiles and Fashion: Materials, Design and Technology Edited by Rose Sinclair

- A Novel Green Treatment for Textiles: Plasma Treatment as a Sustainable Technology By Chi-wai Kan

- Forensic Examination of fibers, Third Edition Edited by James Robertson, Claude Roux and Kenneth G Wiggins

- Chemical Technology in the Pre-Treatment Processes of Textiles by S. R. Karmakar

You may also like:

- What is Rayon Fiber | Types, Properties, Structure & Manufacturing Process of Rayon

- Viscose Rayon: A Regenerated Cellulosic Fiber

- Nylon 66 Fiber: Preparation, Properties and Applications

- Different Types of Man Made Fibers with Their Application

- Nylon: The First Synthetic Fiber

- Acrylic Fiber: Properties, Production Flowchart and Application

- High Performance Polyethylene Fibers – An Overview

- Aramid Fibers: Types, Properties, Manufacturing Process and Applications

- Spandex Fiber: Properties, Manufacturing Process and Uses

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. He is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.